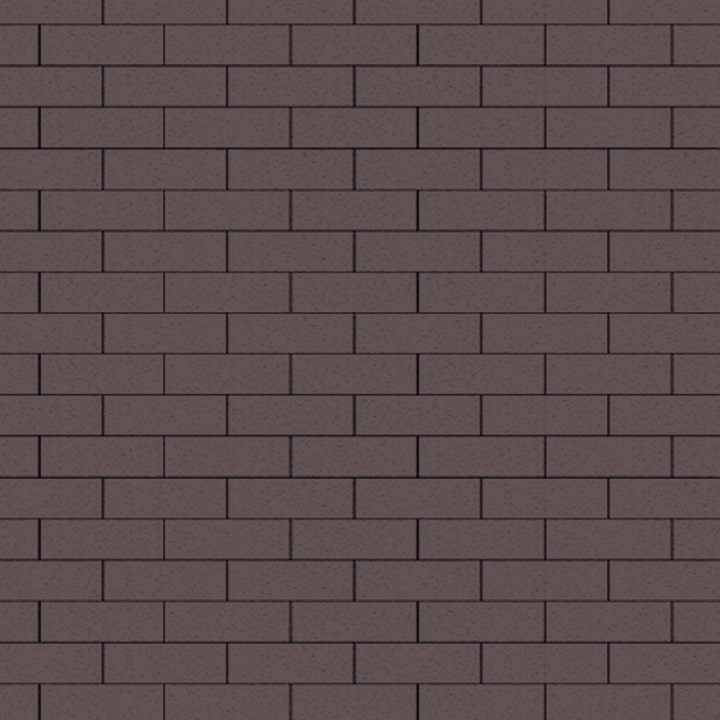

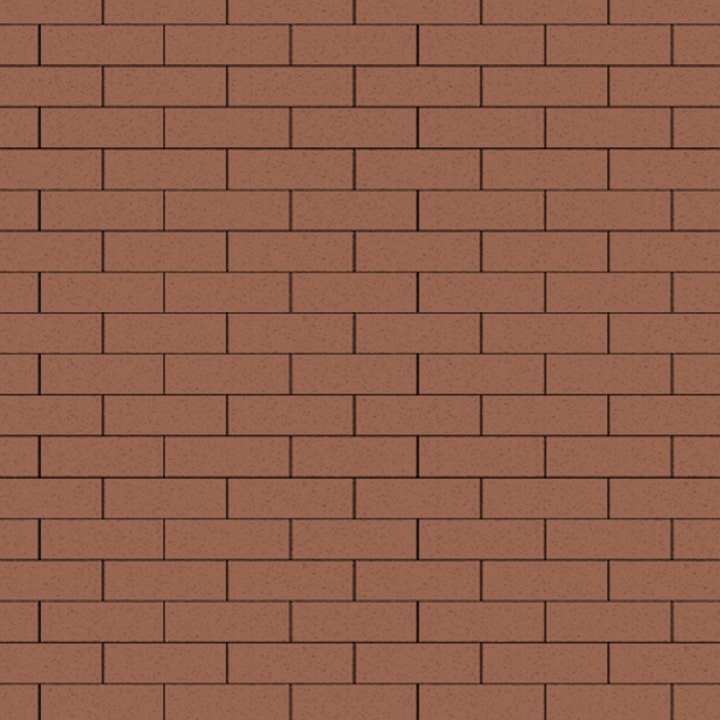

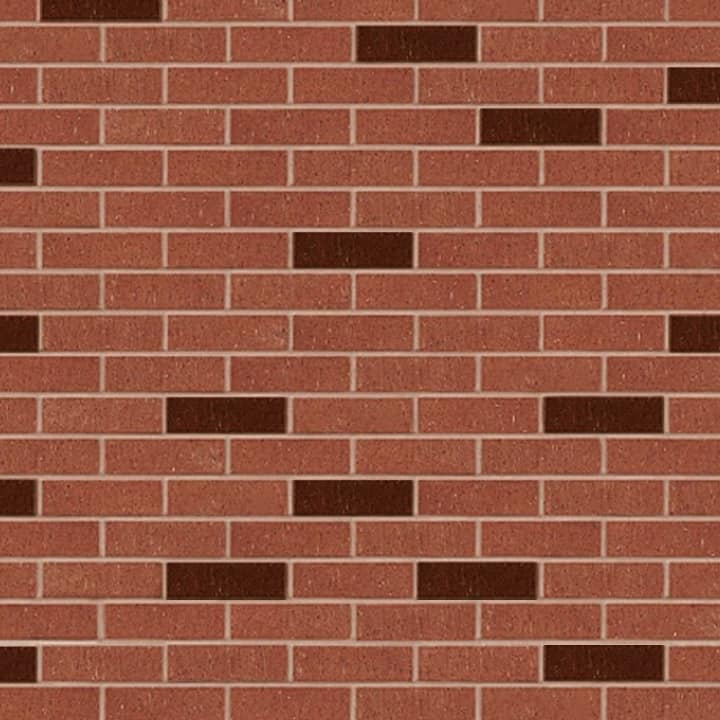

BIPV Tempered Laminated Glass – Ultra-Durable Facade Solutions

Maximum Strength Engineering for Extreme Environments

Nuestra BIPV tempered laminated glass represents the pinnacle of mechanical strength and thermal resilience for challenging architectural applications. Combining the impact resistance of tempered glass with the safety benefits of laminated construction, these panels deliver unmatched durability for high-stress environments including coastal installations, industrial facilities, and extreme climate zones.

Advanced Tempering & Lamination Technology

Dual-Process Manufacturing Excellence Our proprietary manufacturing combines two critical strengthening processes:

- High-Temperature Tempering: 680°C furnace treatment creates surface compression stress exceeding 69 MPa

- Precision Lamination: Advanced PVB interlayer bonding maintains structural integrity even after glass breakage

- Controlled Cooling Process: Computer-controlled quenching creates optimal stress distribution patterns

- Post-Lamination Quality Control: 100% stress pattern analysis ensures uniform strengthening across entire panels

Superior Material Integration

- Premium PVB Interlayer: 0.76mm architectural-grade polyvinyl butyral provides exceptional adhesion strength

- Tempered Glass Substrate: 5.5mm thickness optimized for maximum strength-to-weight performance

- Enhanced Cell Protection: Monocrystalline cells benefit from dual-layer mechanical protection

- Innovación en sellado de bordes: Structural silicone edge seal prevents moisture ingress for 30+ years

Extreme Environment Performance

Storm & Hurricane Resistance Engineered specifically for severe weather environments:

- Impact Velocity Resistance: Withstands 45 m/s projectile impacts without structural failure

- Category 5 Hurricane Compliance: Tested to 250+ mph wind speeds with debris impact simulation

- Thermal Shock Resistance: Rapid temperature changes from -40°C to +85°C without cracking

- Hail Impact Protection: Class 4 hail resistance exceeds insurance industry requirements

Coastal Environment Optimization

- Salt Spray Corrosion Resistance: 5000-hour salt fog testing without performance degradation

- UV Radiation Stability: Enhanced UV absorbers prevent polymer degradation in high-altitude installations

- Moisture Barrier Excellence: <0.1g/m²/day water vapor transmission rate

- Marine Installation Proven: 10+ years field performance in offshore platform applications

Industrial-Grade Electrical Specifications

High-Capacity Power Systems

- Maximum Fuse Rating: 30A capacity handles high-current applications for industrial installations

- 1500V System Voltage: Reduces electrical infrastructure costs for large-scale industrial projects

- Enhanced Current Handling: Oversized conductors and junction boxes accommodate peak current conditions

- Grid-Tie Compatibility: Complies with utility-scale interconnection requirements

Superior Temperature Performance

- Industry-Leading Coefficients: -0.29%/°C power degradation minimizes hot climate losses

- Alcance ampliado: Validated performance from -40°C to +85°C extreme conditions

- Thermal Stability: Minimal voltage drift across temperature extremes ensures consistent power output

- Hot Climate Optimization: Maintains 85% rated output at 70°C cell temperature

Heavy-Duty Applications & Markets

Industrial Facility Integration

- Manufacturing Plants: Rooftop and facade installations for energy-intensive industrial operations

- Warehouse & Distribution: Large-scale installations providing peak demand reduction

- Mining & Extraction: Remote facility power generation in harsh environmental conditions

- Chemical Processing: Corrosion-resistant construction suitable for aggressive chemical environments

Infrastructure Project Applications

- Transportation Terminals: Airport, seaport, and rail facility facade and canopy installations

- Water Treatment Plants: Municipal and industrial facility renewable energy integration

- Data Centers: Mission-critical facility backup and peak shaving power generation

- Military Installations: Secure facility renewable energy for energy independence

Enhanced Safety & Security Features

Post-Breakage Safety Performance Tempered laminated construction provides unique safety characteristics:

- Retained Structural Integrity: Glass fragments remain bonded to PVB interlayer preventing dangerous fallout

- Continued Operation: Electrical generation continues even after glass cracking events

- Impact Absorption: Laminated construction distributes impact forces across entire panel area

- Emergency Egress: Breakage pattern allows emergency breakthrough while maintaining barrier function

Security & Vandalism Resistance

- Forced Entry Deterrence: Multiple impact resistance exceeding standard security glazing

- Anti-Theft Design: Integrated mounting systems prevent panel removal without specialized tools

- Graffiti Resistance: Surface hardness and chemical resistance simplify cleaning and maintenance

- Surveillance Integration: Transparent areas accommodate security camera and sensor installation

Advanced Manufacturing & Quality Systems

Process Control Excellence

- Statistical Process Control: Real-time monitoring of tempering temperature, cooling rate, and lamination pressure

- Automated Inspection: Machine vision systems detect micro-cracks, inclusion, and optical distortions

- Batch Traceability: Complete materials tracking from raw silicon to finished panel installation

- ISO 9001:2015 Compliance: Certified quality management systems ensure consistent product quality

Performance Validation Testing

- Accelerated Life Testing: 10,000-hour combined UV, thermal, and humidity exposure simulation

- Mechanical Fatigue Testing: 1 million cycle loading simulates 25+ years of wind loading

- Electrical Stress Testing: High-voltage insulation and ground fault testing exceeds safety requirements

- Field Performance Correlation: Laboratory results validated through 500+ field installation monitoring

Installation & Structural Integration

Heavy-Duty Mounting Systems

- Enhanced Load Capacity: Mounting hardware designed for 150% safety factor above design loads

- Seismic Qualification: Zone 4 earthquake resistance with flexible connection details

- Thermal Expansion Accommodation: Sliding connections handle differential expansion between glass and structure

- Corrosion-Resistant Hardware: Marine-grade stainless steel and aluminum components for coastal installations

Professional Installation Requirements

- Specialized Training: Installers require tempered glass handling certification and safety training

- Crane & Rigging: Large format panels require professional rigging equipment and techniques

- Weather Restrictions: Installation protocols for wind speed, temperature, and precipitation limits

- Safety Protocols: Enhanced fall protection and glass handling procedures for worker safety

Long-Term Durability & Performance

Extended Service Life Design

- 40-Year Design Life: Materials and construction engineered for extended service in harsh environments

- Minimal Degradation: <0.5% annual power degradation rate based on accelerated aging studies

- Maintenance-Free Operation: Self-cleaning glass coating and robust construction minimize upkeep requirements

- Component Longevity: All system components selected for matched 40-year service life expectancy

Field Performance Validation

- Global Installation Database: Performance data from 2000+ installations across diverse environments

- Extreme Environment Proof: Documented performance in desert, arctic, coastal, and industrial environments

- Reliability Statistics: <0.1% annual failure rate based on 15+ years of field performance data

- Customer Satisfaction: 98% customer satisfaction rating for durability and performance

Comprehensive Support & Service

Technical Engineering Support

- Custom Design Services: Site-specific engineering for unique installation requirements

- Structural Analysis: Finite element analysis for complex loading and mounting conditions

- Code Compliance: Professional engineer stamped drawings for building permit and inspection

- Installation Training: Hands-on training programs for installation contractors and building teams

Extended Warranty Protection

- 30-year linear power warranty: Guaranteed minimum 80% output retention after 30 years

- 20-year product defect warranty: Complete coverage of materials, workmanship, and manufacturing

- Structural integrity guarantee: 25-year protection against breakage, delamination, and seal failure

- Performance monitoring: Optional IoT monitoring with 25-year data logging and analysis